TANG PRIZE / Tang Prize winner Omar Yaghi hails chemistry as a climate solution

09/28/2024 05:35 PM

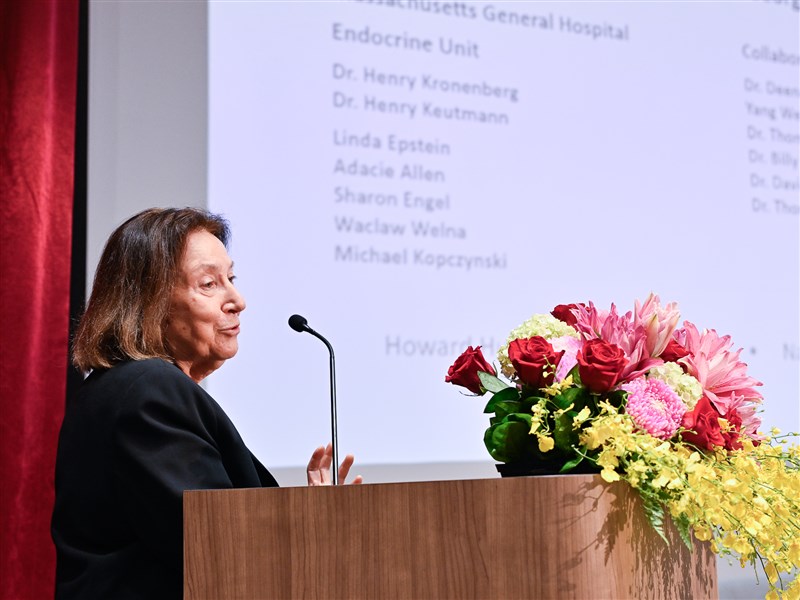

Climate problems can be addressed with reticular chemistry, 2024 Tang Prize in Sustainable Development awardee Omar M. Yaghi proclaimed in his laureate lecture in Taipei on Saturday as he described the new field of chemistry he has pioneered.

(Full text of the story is now in CNA English news archive. To view the full story, you will need to be a subscribed member of the CNA archive. To subscribe, please read here.)

More in TANG PRIZE

-

![Drugs treating diabetes, obesity can do more: Tang Prize laureates]() Drugs treating diabetes, obesity can do more: Tang Prize laureatesSvetlana Mojsov and Jens Juul Holst, two of the laureates of the 2024 Tang Prize in Biopharmaceutical Science, said at a forum in Taichung on Tuesday that the GLP-1-based drugs their research spawned could go beyond managing diabetes and obesity.10/01/2024 08:52 PM

Drugs treating diabetes, obesity can do more: Tang Prize laureatesSvetlana Mojsov and Jens Juul Holst, two of the laureates of the 2024 Tang Prize in Biopharmaceutical Science, said at a forum in Taichung on Tuesday that the GLP-1-based drugs their research spawned could go beyond managing diabetes and obesity.10/01/2024 08:52 PM -

![Tang Prize winner lauds Taiwan implementation of human rights covenants]() Tang Prize winner lauds Taiwan implementation of human rights covenantsFormer Irish President Mary Robinson on Monday praised Taiwan's efforts to incorporate international covenants on human rights into its domestic law despite not being a signatory.09/30/2024 08:58 PM

Tang Prize winner lauds Taiwan implementation of human rights covenantsFormer Irish President Mary Robinson on Monday praised Taiwan's efforts to incorporate international covenants on human rights into its domestic law despite not being a signatory.09/30/2024 08:58 PM -

![Historian shares research into ancient Chinese myth at Tang Prize forum]() Historian shares research into ancient Chinese myth at Tang Prize forumRenowned Taiwanese-American historian Hsu Cho-yun (許倬雲) on Monday said his work regarding the ancient Chinese myth Da Yu (大禹) was a successful example of integrating social science methodologies into historical research that helped him win the 2024 Tang Prize in Sinology.09/30/2024 01:52 PM

Historian shares research into ancient Chinese myth at Tang Prize forumRenowned Taiwanese-American historian Hsu Cho-yun (許倬雲) on Monday said his work regarding the ancient Chinese myth Da Yu (大禹) was a successful example of integrating social science methodologies into historical research that helped him win the 2024 Tang Prize in Sinology.09/30/2024 01:52 PM

Latest

-

Sports

Shuttler Lin Chun-yi reaches All England Open final

03/07/2026 10:11 PM -

Business

Ex-insurance executive detained in NT$50 million investment fraud

03/07/2026 09:20 PM -

Sports

Taiwan beats Vietnam 1-0 at AFC Women's Asian Cup

03/07/2026 08:56 PM -

Culture

109-year-old Kalinga tattooist keeps legacy alive

03/07/2026 08:43 PM -

Cross-Strait

Annual Taipei march marks Tibetan uprising, warns Taiwan of China threat

03/07/2026 07:53 PM